With CNC, your digital tooling will have a bigger productivity impact than any of your “real” tooling. Or, in another case, they are proud that they have a name brand and not a clone Haimer 3D Taster or Blake Coaxial Indicator, but they want a cheap or free piece of CNC Software. It doesn’t take many cutters saved for very long to completely pay for that feeds and speeds calculator! I’ve talked to machinists who spend hundreds on custom ground cutters and want to preserve their life as long as possible, but balk at $79 for a sophisticated feeds and speeds calculator that is the key to extending that tool life. Some machinists are funny about Digital Tooling.

#Cnc simulator software software

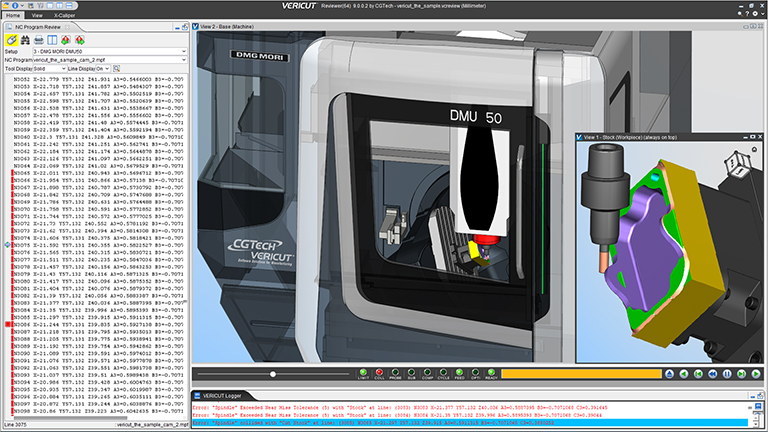

There are many other kinds of CNC software, which I’ve taken to calling “Digital Tooling”, that are important to CNC work.ĭigital Tooling: We need CNC Software as much as hard tooling to be successful CNC’ers… G-Code editors and feeds and speeds calculators were not far behind. At the very least, I needed a CAD program to make drawings which I would then feed to a CAM program to generate the gcode needed to be really productive with the machine. But suddenly, I had a whole new category of tooling to add. Though I might like to have a 4th axis, I didn’t need a rotary table, for example. Then I went CNC, and I started noticing a lot of that tooling wasn’t needed any more.

0 kommentar(er)

0 kommentar(er)